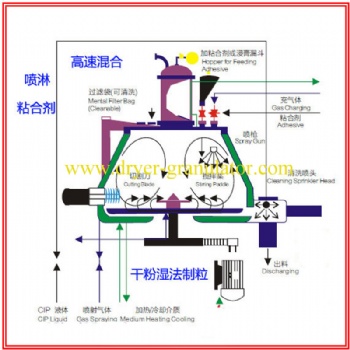

high speed shear mix granulator

Equipment principle:

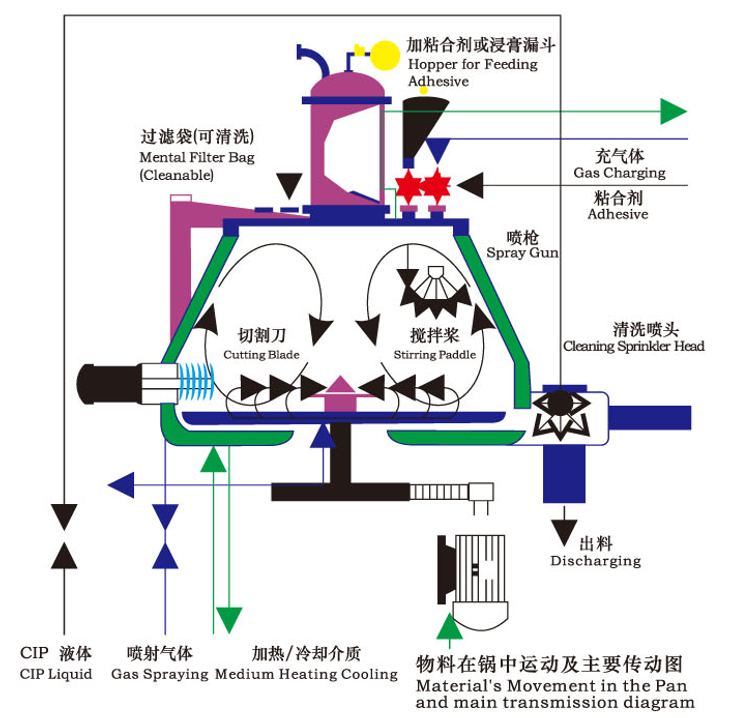

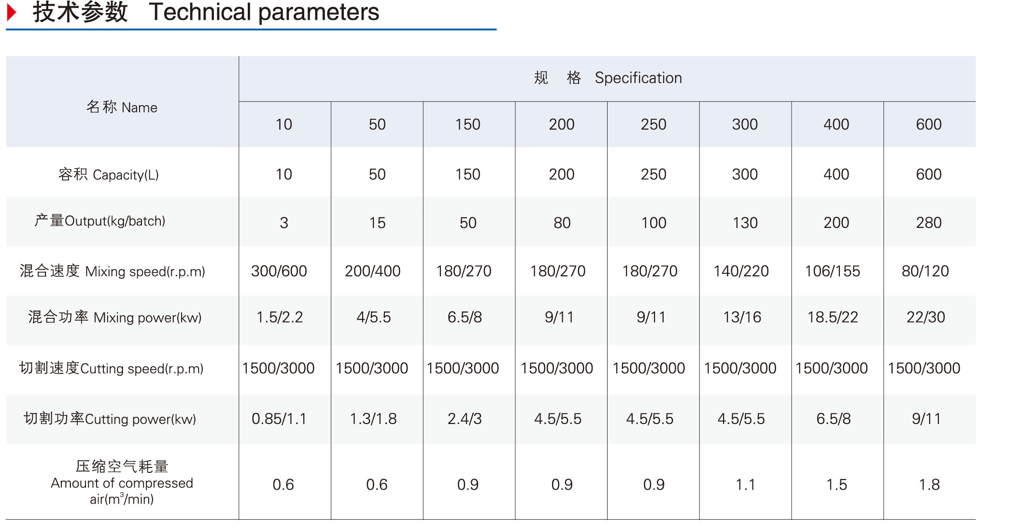

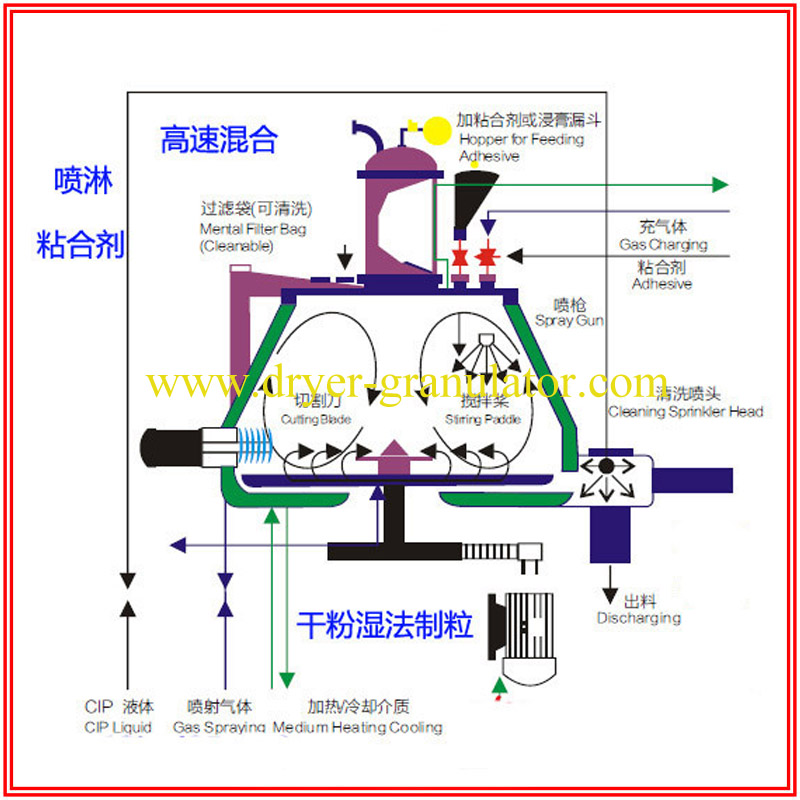

The powder material and the binder are fully mixed from the bottom mixed slurry in a cylindrical container to form a wet soft material, and then cut into uniform wet particles by a side-mounted high-speed crushing paddle. The high-speed mixing granulator is supported by the fuselage, the pot is the container, the stirring rotation and the cutting flying knife drive are the driving force, the material is stirred by the stirring blade, so that the material is tumbling and mixing uniformly in a short time, and then made by the cutting flying knife. The particles are finally removed from the discharge port, and the rotation speed of the stirring and cutting flying knife is changed, so as to obtain equipment of different sizes of particles.

▼ Application scope:

The high-efficiency wet mixing granulator is a new granulation process adopted in the pharmaceutical, food and feed industries in my country in the 1980s. This machine integrates mixing and granulation. Its biggest advantage is that the granulation speed is fast, the effect is good, and the range is wide. Used in the following industries:

The production of tablets in the pharmaceutical industry can provide ideal granular raw materials for the tableting process.

Granulation in the food industry: such as chemical condiments, dairy products, spices, spices, sour products, food additives, food coloring, etc.

Features:

◎The machine adopts a horizontal cylindrical structure with a reasonable structure.

◎Pneumatic sealed drive shaft can be switched to water during cleaning.

◎Fluidized granulation, the granulation is approximately spherical, and the fluidity is good.

◎Compared with the traditional process, 25% binder is reduced, and the drying time is shortened.

◎Each batch only needs 2 minutes for dry mixing and 1-4 minutes for granulation. The work efficiency is increased by 4-5 times compared with the traditional process.

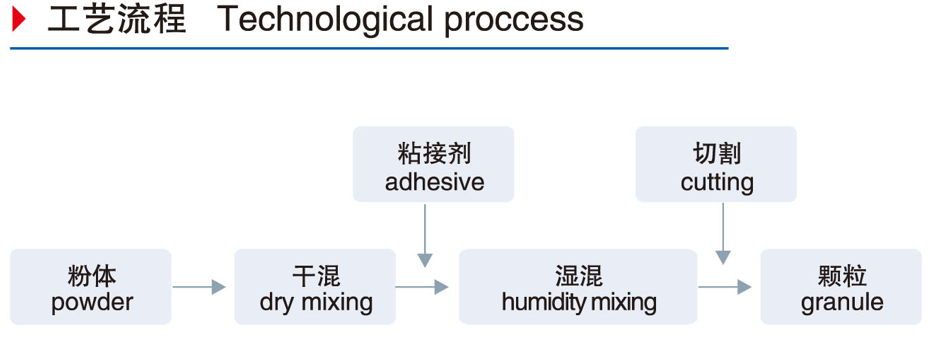

◎Completed in the same closed container, dry mixing-wet mixing-granulation, the process is shortened.

◎The entire operation has strict safety protection measures.

◎It can be made into a jacket type according to user requirements.

Categories

Contact Us

- +86-182-62545965

- +86-18262545965

- unackdry@163.com

- unackdry@outlook.com

- +8618262545965

售前客服

售前客服